Power Solutions

Worldwide success with combined heat and power generation.

A combined heat and power module is the ideal solution for everyone seeking to reduce energy costs in the long term and free themselves of rising electricity prices. As a pioneer, innovator working with leading manufacturers of decentralised energy generation systems using combined heat and power (CHP) in the world, OG Power work with companies that have commissioned thousands of technologically advanced and high efficient CHP plants since 1995.

Satisfied customers all over the world confirm the quality, performance and reliability of our solutions.

The product range includes CHP plants and electrical generation only plants with an electrical output range of 4 kW to 4,000 kW

Combined Heat & Power Generation. Highly efficient and environmentally friendly.

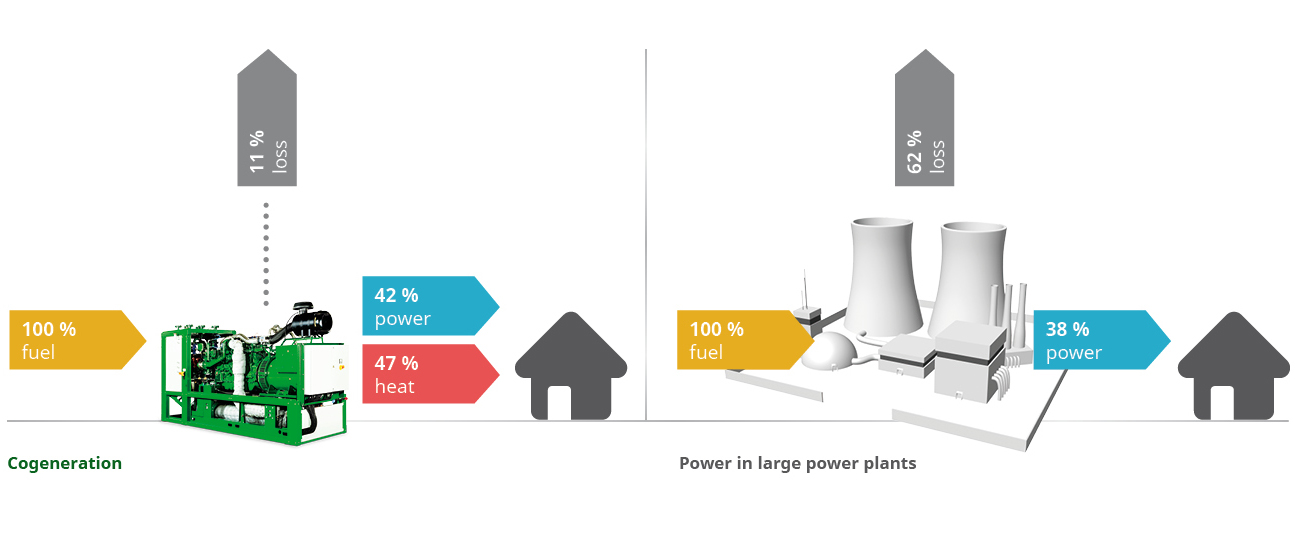

The simultaneous generation of mechanical energy and useful heat is called combined power and heat (CHP) generation. While the mechanical energy is converted directly into electricity, the heat can be used to heat, cool or generate steam. The heat resulting from the electricity generation therefore does not simply escape into the atmosphere unused, but is put to good use. This makes combined heat and power technology so efficient and environmentally friendly. Up to 40 percent of primary energy is saved. CO2 emissions fall by up to 60 percent compared to conventional electricity generation in large power plants.

Combined Heat & Power Generation. Highly efficient and environmentally friendly.

The simultaneous generation of mechanical energy and useful heat is called combined power and heat (CHP) generation. While the mechanical energy is converted directly into electricity, the heat can be used to heat, cool or generate steam. The heat resulting from the electricity generation therefore does not simply escape into the atmosphere unused, but is put to good use. This makes combined heat and power technology so efficient and environmentally friendly. Up to 40 percent of primary energy is saved. CO2 emissions fall by up to 60 percent compared to conventional electricity generation in large power plants.

Combine cleverly and save even more energy.

Ventilating offices, generating hot steam for the food industry and tipping the scales when it comes to a stable decentralised energy supply of the future. Combined heat and power generation does all of that. And a highly efficient power plant by OG Power especially. Especially if innovative energy concepts are involved. In combination with absorption chillers, steam generators and heat accumulators. Or integrated in virtual power plants for the stabilisation of the electricity grid

Accumulating heat.

By integrating a heat accumulator, the heat production can be isolated from electricity production allowing the OG Power plant to be used flexibly.

Cooling with heat.

Using an absorption chiller, the heat produced from combined heat and power generation is converted and used for environmentally-friendly room ventilation, for example.

Raising the temperature.

Integrated in steam, hot water and thermal oil applications, OG Power plants can provide customised solutions, such as for the food industry.

Post-treating exhaust gas.

By integrating catalyst technology into a OG Power plant, harmful substances, small quantities of which are still contained in the exhaust gas, are removed thus ensuring that the TA Luft regulations are met.

Processing gas.

After the natural fermentation process, biogas often still contains residues of substances such as sulphur. Biogas is processed using activated coal filters and gas cooling.

Replacing the grid.

It is not always possible or practical to connect to a stable electricity grid. OG Power plants are suitable for standalone operation and can provide backup power in emergencies.

Continuously variable controlling.

Unlike major power plants, CHP plants can regulate the output within a very short time. OG Power plants are continuously variable between 50 and 100 percent of the output range and adapt to the actual energy requirements using modern controlling technology.

Virtual power plant.

OG Power plants are equipped with a special interface enabling their simple connection to virtual power plants and therefore allowing them to participate in the Electricity Balancing Market.